FAQ Boating

ARTICLE

How is FlexDry disposed of?

The FlexDry consists of non-hazardous granules of calcium chloride and starch, so it can be disposed of with household waste.

How does the FlexDry work?

The FlexDry absorbs up to 200% of its own weight in moisture. Depending on the ambient climate, this is effective for several months. The absorbed moisture turns into a gel and is never liquid. Unobtrusive, flexible placement is possible thanks to its compact dimensions.

What is FlexDry? Where can I use FlexDry?

FlexDry offers long-term protection against moisture. It reduces high relative humidity in closed rooms with little or no ventilation. FlexDry offers protection against mold, corrosion (rust), mildew stains, fogged windows or bad odors.

FlexDry has a very wide range of applications. It is suitable for boats, caravans, sheds, distribution cabinets, attics, cellars, crawl spaces, guest rooms, checkrooms, garden sheds, safes, washrooms, etc.

Blöcke

Can I use a wire rope in a standard block?

Absolutely not! Most standard blocks use plastic washers that cannot withstand the requirements (steel in the wire rope).

Can I use a wire rope block with a synthetic rope?

In most cases, you can use synthetic ropes in a wire rope block, as the sheave harmonizes very well with the braided rope.

What advantages does the S block series have over the old series?

The S block series is an improved version of the old series that is constantly being developed further. The design has been revised; the recognition value is high.

The following points have been improved:

- Optimum dew guidance thanks to curved side sections

- Dimensionally stable continuous stainless steel tab for more stability and safety

- Indication of the maximum rope thickness and bearing type in the reinforcement flap

- wobble riveting prevents sharp burrs on the rivet head

- Side parts made of high-quality, fiberglass-reinforced plastic (UV-resistant)

- Compact design, low overall height

- Also available in needle bearing

How do I mount a block correctly?

A block can only function properly if it can move freely so that it always runs in the direction of pull of the cordage or wire. If the block is tilted so that the cordage is in contact with the block jaw under load, the block will be damaged. In the worst case, the cordage can become jammed between the suspension and the pulley.

Jamming of the cordage in the block can in turn pose a great danger to the ship and crew. Appropriate precautions and checks of the individual block applications are therefore urgently recommended.

When do I use needle bearing blocks?

Needle roller bearings - also known as roller bearings - are the best bearings for high-quality and resilient blocks. The contact surfaces are much larger than those of balls. They can therefore support higher loads and remain "rollable". Needle roller bearings are therefore used for very high working loads. A needle roller bearing combines the advantages of plain and ball bearings.

When do I use plain bearing blocks?

In a simple plain bearing, the block washer runs on an axle. The washer material is made of nylon or other sliding materials, for example. When using high-quality material and an axle with the largest possible diameter, these "simple" blocks are very durable, maintenance-free and roll evenly well. This type of bearing is particularly suitable for standing loads.

When do I use ball bearing blocks?

Smooth-running ball bearing blocks are ideal for all areas where lines need to be hauled quickly and largely by hand. For example, for the single-line reefing system or when deflecting sheets as well as for the lines for hauling and furling the traveler. Trimming then becomes much more sensitive, especially in light winds. The use of ball bearings is a significant advantage, especially on small boats where most lines are run by hand.

What do the numbers on the blocks mean?

The numbers in the reinforcement flaps indicate the maximum cordage strength.

What types of bearings are available for Sprenger blocks?

The Sprenger S block series is available in three bearing versions.

The bearing type of the block can be recognized at first glance in the reinforcement tab.

Here we find a yellow dot for the plain bearing, a red dot for the ball bearing and a blue dot for the needle bearing.

How can the blocks be damaged?

Damage to blocks can occur due to overloading as a result of undersizing, patent jibes, but also due to use with bows - although a swivel would be appropriate.

In such a case, the block is forced into a rotational movement by the sheet, which cannot be compensated for by the missing swivel. As a result, the sheet no longer runs over the roller, but into the side part. The resulting forces severely deform and destroy the block. Therefore, whenever possible, use blocks with swivels.

Are Sprenger blocks suitable for use in salt water?

Yes, Sprenger blocks are suitable for use in salt water. Nevertheless, rust may form, especially on and around the rivet. Unfortunately, this cannot be avoided, but does not affect the quality. These are the smallest/minimal residual particle deposits from the machining tools. However, this "rust build-up" is only superficial and can be easily removed.

What are buoys?

Buoys are a combination of blocks and ropes designed to make work easier. They are used in a variety of ways as mainsheets, spreaders, boom vang and on the traveler of dinghies. With our Sprenger blocks, a wide variety of tackle combinations are possible. You will also find a selection of complete tackles in our range.

Beschläge

For which boats are Sprenger fittings suitable?

Sprenger fittings are for boats and yachts up to approx. 10 m length. We have a wide range of products in this area.

Lüa = length over all

=from the foremost to the rearmost fixed point (bow - stern)

Why should I choose Sprenger fittings?

With Sprenger you have the fittings with the best price/performance ratio on the market. In tests carried out by the well-known magazines YACHT and SEGELN, Sprenger blocks were the test winners and achieved the highest scores. The working and breaking loads, the catalog specifications in accordance with the actual values and the corrosion resistance were tested.

You may be familiar with the famous sailor Wilfried Erdmann. He circumnavigated the globe in around 330 days in 1984. About 20 years later, he repeated this single-handed circumnavigation, this time even against the prevailing wind directions. Not only did he use the same boat for both circumnavigations, he also used the same Sprenger blocks for the most part. Is there any better proof of the durability and quality of Sprenger fittings?

But our fittings are not only popular with circumnavigators. Sprenger products are also very popular with cruising and regatta sailors.

Schotklemmen

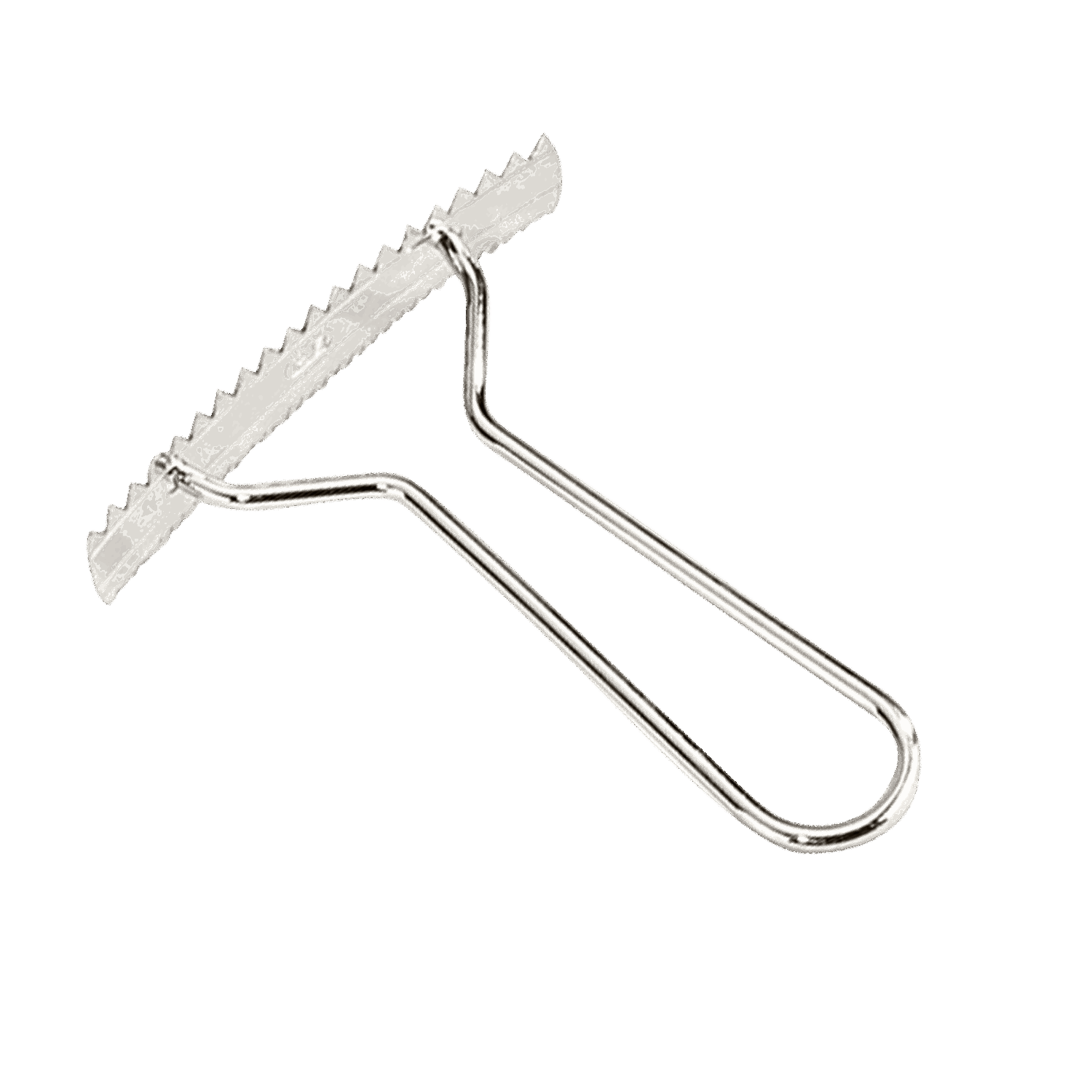

What are sheet clamps (also known as curry clamps) used for and how do they work?

Sheet clamps are designed to enable the quick attachment and easy release of running rigging.

By loading the line in one direction, the toothed clamping jaws of the clamp close and block the rope with a special spring mechanism that presses the jaws against the inserted rope. To cast off, the end of the rope is pulled upwards and it runs freely again. There is therefore no need to attach it to the cleat. This means that the line can be released very quickly and the line can be pulled when it is loaded.

VC® 17m

How can VC® 17m be painted over?

- Overpainting with VC® Offshore EU

a. The simplest variant is overcoating with VC® Offshore EU. The hard antifouling is compatible with VC® 17m. The latter must be roughened thoroughly with sandpaper. Apply 1 coat of diluted VC® Offshore EU with 5-10% VC® General Thinner. Apply the second and possibly third coat with little or no thinner. The drying time between the individual coats is 1.5-2 hours.

2. remove VC® 17m and recoat with VC® Offshore EU

a. Remove VC® 17m with coarse sandpaper and apply two new coats of VC® Tar to the old VC® Tar. Apply the first coat of VC0174 Offshore EU at a temperature of 23°C between 3h and max. 6h after the last coat of VC® Tar. Apply the second and third coat after 1.5-2 hours.

3. remove VC® 17m and recoat with International® Ultra 300

a. Remove VC® 17m with coarse sandpaper and apply two new coats of Gelshield® 200 to the old VC® Tar coat. Then apply 2-3 coats of International® Ultra 300.

4. change to biocide-free antifouling B-Free Explore

a. Sand VC® 17m with 80-120 grit sandpaper, then apply 1 coat of B-Free Conversion Coat, followed by 1 coat of B-Free Tiecoat and 2 coats of B-Free Explore.

What can VC® 17m be replaced with?

The simplest option is to paint over with the hard antifouling VC® Offshore EU. Alternatively, you can switch to the biocide-free B-Free Explore . This silicone-based fouling protection prevents fouling due to the smooth surface, has a positive effect on fuel consumption and has a self-cleaning effect when moving in water.

GENERAL

What is the difference between the safe working load and the breaking load?

The safe working load indicates the load with which a block can be permanently stressed without becoming non-functional. The breaking load, on the other hand, describes the load at which the object (block) breaks or ceases to function. We recommend a safety factor of at least four.

Example: Breaking load specification in the catalog: 1000 kg corresponds to a working load of 250 kg (breaking load:4).

This fourfold safety is the basis in the chain industry. This means that with a determined breaking load of 1,000 kg, for example, 50% of this is taken as the test load. No residual deformation should occur at this value. Half of the test load is then the safe working load, in our example 250 kg.

How can I recognize Sprenger products?

All Sprenger products are stamped with the HS logo "HS-Germany". This stamp is a recognizable feature of every Sprenger product and stands for quality "Made in Germany".